Ballbar Analysis setup interpretation and programming using a Renishaw QC10 Ballbar

What is a Ballbar?

This is a precision measurement tool that collects axis movement when moving in circular motion. The Ballbar test will measure any deviation the machine makes from a perfect circle, recording data as the two axes work together. Errors such as backlash, level/squareness, servo mismatch, reversal spikes, vibration, stick slip and other problems can be determined. Users can be useful in determining what feedrate delivers the best accuracy by running the test at different feedrates. A longer length may be used to increase sensitivity to geometry errors, such as squareness; while a very small radius bar may be used to highlight errors such as servo mismatch.

|

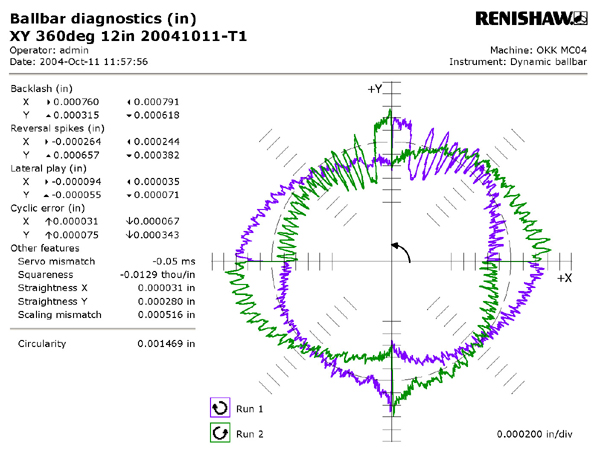

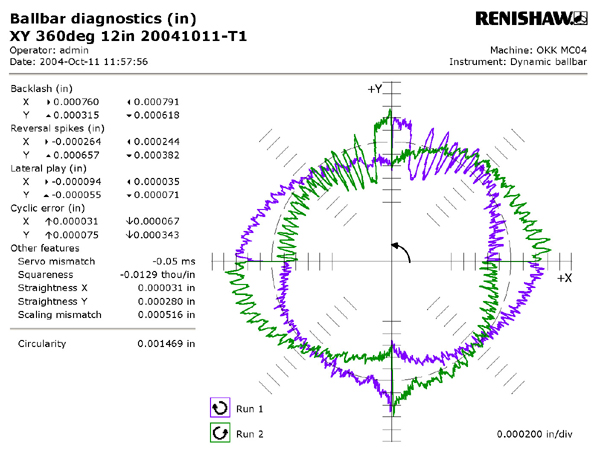

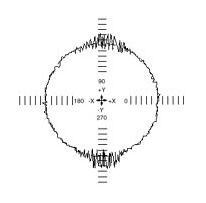

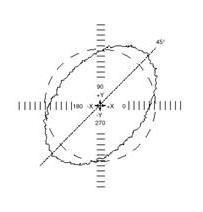

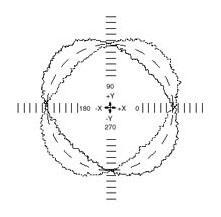

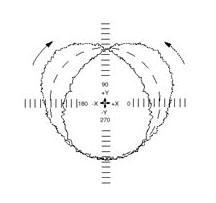

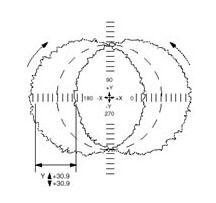

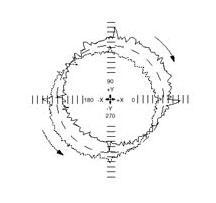

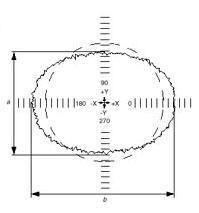

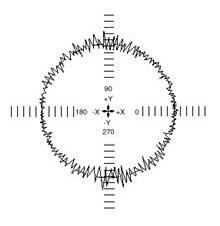

Sample Renishaw 5 ballbar Plots

|

|

Sample ballbar XY interpolation program

O1001(XY BALLBAR)

G1G90G54X-3.997Y0Z0F50.

M00

G1X-3.937F50.

G17G2I3.937

G17G2I3.937

G1X-3.997

M00

G1X-3.937

G17G3I3.937

G17G3I3.937

G1X-3.997

M99

|

When is a ballbar primarily used?

Ballbar is used for primarily preventative, predictive maintenance and for determining problems which are hard to tell by the use of indicators. Usually, a good service tech can figure out what is wrong before it is necessary to do a ballbar test. Plots are usually compared at looking for some change in the plot and can hopefully catch the problem early. The graph is also a great way to show the boss how accurate the machine is.

|

See Renishaw website for more information related to Renishaw ballbar equipment.

|

Is the ballbar plot always accurate?

Yes and No. One thing to remember is the tests are carried out under no load conditions. Therefore, it does not take into effect on any cutter or machine deflection due to any mechanical or thermal loads caused by the workpiece, fixture or machining process.

Looking for someone to analyze a ball bar plot? Ballbar analyzing service available from the CNC Specialty Store

|

|

|

|

When would I have a ballbar check done if it were only once??

When the machine is brand spanking new.

That way you have something to compare it to down the road, so you have a map of the machine. Also, if it does find a problem you can go to the dealer immediately and ask them to take care of your problem under warranty.

|

|

Ballbar 5 Plot analysis and ballbar

|

|

|

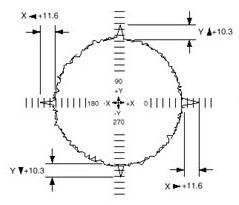

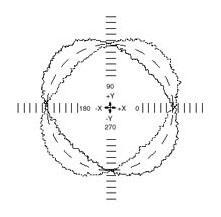

Explanation of Ballbar plots and typical repairs actions to take

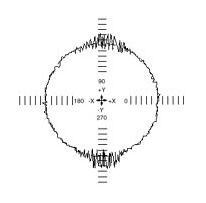

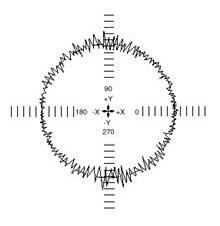

- Axis reversal spikes. When an axis is being driven in one direction and then has to reverse and move in the opposite direction, instead of reversing smoothly it may pause momentarily at the turnaround point. This appears as short spikes that appear on either axis reversal point. This could mean servo response time is poor and excessive friction in axis.

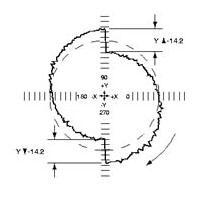

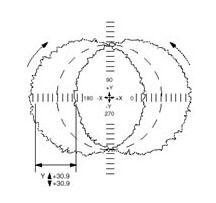

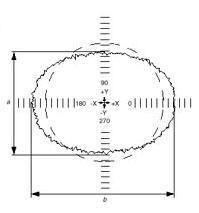

- Scale mismatch is shown as an oval plot, extended along one axis. One of the machine axes is either over traveling or under traveling relative to the other. One axis could be feeding too far or the other is not feeding far enough, possibly due to overheating or a faulty ballscrew. Servo loop gains may need adjustment.

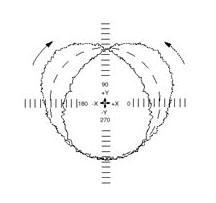

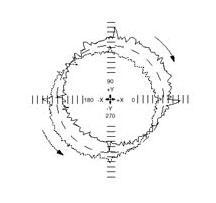

- Backlash- If positive backlash it could be ballscrew end float, worn drive nut,or guide way play. If negative backlash the machine parameter might be overcompensated. If unequal backlash then there could be a wind up in the ballscrew where it becomes stiff on one end of the travel. It also typically occurs on a vertical axis and can also be caused by any counterbalance mechanisms or weight.

- Stick-slip results when friction causes one axis to stick when it is fed at a very low rate. Left unchecked, this error could prevent the machine from producing an acceptable surface finish. Guideways or bearings could be bad or damaged. Improper lubrication or power can be supplied to overcome friction.

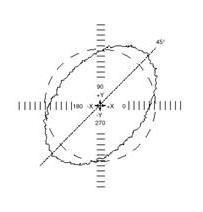

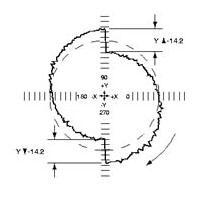

- Squareness error is shown in an oval ballbar plot It occurs when normally orthogonal axes are no longer moving at 90°, relative to one another. This may be due to a bent axis or some other misalignment. This squareness error oval tilts at 45° with respect to the two axes, and remains in the same position regardless of the direction of travel of the ballbar (CW or CCW).

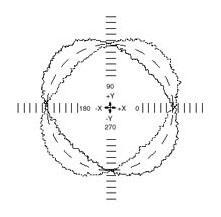

- Servo mismatch is shown as an oval plot tilted by 45° that does not stay in place - It shifts back and forth by 90° depending on the direction of travel. This indicates mismatched servo gains in the CNC, causing the axis with the higher gain to lead the other, and makes a precise circular interpolation impossible.

- Cyclic error is shown as a plot with waviness that varies in amplitude and reaches a maximum amplitude at axis reversal. This error is caused by a flaw in the axis leadscrew or leadscrew mounting. If only in one half of plot on a vertical axis it may have to do with a counterbalance type problem.

- Master/slave change over error often results on CNC's that can only interpolate one axis at a time. Varying the speed of the master axis while the slave axis follows generates arcs. This changeover error produces a plot with 45° steps, and may make precision machining of circular features impossible.

- Lateral Play is caused by looseness in the gibs or guide ways causing a fish tail effect. When machining interpolated holes you will tend to get an oval shaped hole.

- Offset change/Plot discontinuity/Plot rotation/Radius change/Tri-lobe/spiral- These plots all tend to be setup errors with the ballbar equipment. The tool cup is either damaged, dirty, or walking out of the cup while running the test. It could be an error in the ballbar program you are running. It could also be the joints in the ballbar rods, cup or balls that are loose. It could also be that the computer is slow and not capturing quick enough.

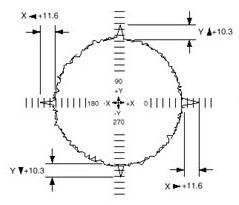

- Straightness or Scaling error Lack of straightness in machine guideways. They may be bent , misaligned, worn or poor machine foundation. Scaling error may be caused by scales encoder or drive.

- Vibration can be invoked by the machine itself, drive train, servo loop, damaged guideways or surrounding environment.

Would you like a second opinion or someone else to analyze the ballbar plot for you.

We offer Ballbar plot analysis as a service of Machinetoolhelp.com. Click Here for more information

|

| Common Ballbar Plots often encountered when analyzing machine tools, and how to analyze. |

|