|

|

Robot Preventative Maintenance PM checks and good practice

(always reference the manuals that come with your robot) |

|

Robot PM Checks or actions to perform |

| Back up Software (both image and separated files if possible) |

| Clean limit switches and check for free movement |

| Replace robot batteries 1/year |

| Replace RAM B/U batteries 1/year |

| Clear alarms and check cycle power after replacing batteries |

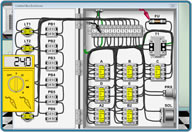

| Clean controller cooling fans, check operation |

| Check fans on drives are running in controller cabinet |

| Check fans exchanging outside air into controller |

| Replace controller air intake filter |

| Control connections |

| Robot cables for damage or wear |

| Robot cable connections |

| Incoming voltage |

| Mechanical hardware for looseness (end of arm tooling, robot base, fixtures, etc.) |

| Axis following error |

| Axis brake functionality |

| Axis vibration- hold hand on axis casting and jog robot in slow and fast speed |

| Axis repeatability and backlash |

| Check belts if used for some of the axis |

|

Robot Grease and oil replacement |

| (Use recommended grease!!! Or Serious damage will occur) |

| Be sure to burp the grease out by moving the robot after pumping through |

| If using a pneumatic or electrical grease gun. Make sure the output pressure is within |

| Robot manufacturers recommendations |

| Move robot to proper position to check oil levels (some models) |

| Axis 1 reducer |

| Axis 2 reducer |

| Axis 3 reducer |

| Axis 4 reducer |

| Axis 5 reducer |

| Axis 6 reducer |

| Axis 7 reducer |

|

|

Gripper type end of arm tooling |

| Check end of arm tooling for loose bolts |

| Check air regulator set properly |

| Clean valving |

| Clean air exhaust mufflers |

| Check air pressure settings |

| Check flow controls if used |

| Check for damaged air lines |

| Check for damaged seals or clean if robot changes tools |

| Check electrical connections and wiring for damage |

|

|

Vacuum type end of arm tooling |

| Check air vacuum line filter |

| Clean valving |

| Clean air exhaust mufflers |

| Check air pressure settings |

| Check for damaged air lines |

| Check for damaged seals or clean if robot changes tools |

| Check electrical connections and wiring for damage |

|

Rotary motion type end of arm tooling |

| Check rotary tool turns freely |

| Check flow controls if used |

| Check regulator pressure if air powered |

| Check for damaged air lines |

| Check for damaged seals or clean if robot changes tools |

| Check electrical connections and wiring for damage |

|

| |

If equipped with linear rails |

| Check CAM followers |

| Check linear guides for wear or spalling |

| Grease Linear guides if required (Do not over grease!!view manufacturers recommendations) |

| Clean limit switches to see if they actuate freely |

|

|

|

|