|

Automation, Integration & machine tool options

Automate Fixture clamping, robotics, conveyors, tool breakage, light curtains, indexers.

|

Fixture clamping considerations

|

- Are M-Codes available? Find this out from the manufacturer. You may have to purchase separately of course at an extra charge. It seems like about 50% of machines come with them.

- Light curtains? Yes if you are clamping with door open

- PLC? Yes, almost always for your safety considerations.

- Servo or Pneumatic door? save some cycle time, prevent repetitive injuries (carpal tunnel). Alerts operators when cycle is finished. USed on robotic cells.

- Do you need to check for part present signals? Yes highly recommended. If the part is not seated, you could throw it, crash machine, rip tool from spindle or many other things.

- Do you want to clamp/unclamp with M-codes? It depends on operation.

- Will you monitor clamp pressure while machining? Always if possible. If part comes loose or is not seated tool could catch part and be ripped from spindle causing severe damage.

- Make sure you tell integrator that clamps must stop moving if power or air is cut off.

- Do you want pneumatic or PLC Sequencing?? Always PLC, Why? Because it can be altered very quickly and easily just by changing the PLC program. Air logic is a complete redesign and it is usually more difficult to troubleshoot.

- Do you want device tags made up for hydraulic and pneumatic pressure settings? Depends on how often adjusted. Its a good idea. Otherwise you have to find the documentation.

- Documentation? Get everything in PDF so you do not need certain Programs to look at it. Also get the original files including parts list and a sequence of operation. Software manufacturers offer readers on their websites for programs if you need to open only.

- Is the main PLC panel going to have three phase in it? You may want to see if the high voltage contactors and transformers can go in main machine tool cabinet. With the new arc flash procedures OSHA is implementing it may or may not affect you. Have someone assess your situation. It will be easier and take less time to troubleshoot for your maintenance people if they do not have to get all suited up every time they enter an electrical cabinet.

|

Light curtains

|

Do I need them? Yes if you have any automation that requires the door to be open. If you have a servo or pneumatic autodoor. Robotics depends on situation. Its not a bad idea to prevent the robot or anything else from being in the opening or closing of door. It is also a good idea for the front of the machine if you may be hand loading if something in the cell is down for a period of time.

|

Tool Breakage detect

|

Do you need it? If you can handle possibly an extra second or two in the cycle, yes definitely do it. If you have an operator running three machines he may be waiting that extra second anyway. You will prevent crashes and downtime. Not to mention the possibility of loosing the contract because of shipping multiple unfinished parts that can slip through the cracks. There are many different types and considerations when selecting.

|

| 3 stage signal lights |

Much cheaper Purchasing separately.

|

| Work Lights |

Much cheaper Purchasing separately.

|

Indexers

|

Does your machine have M-codes available? Some machines this is an option.

Do you want it to be programmable through machine control? If no be aware that operators must make sure they reset both the indexer program and the machine tool program to put them in sink. This can cause many crashes to occur if you do not have good operators.

|

|

Coolant Flush system

|

Look at machine does it look like chips could build up in the corners. Will you have to rely on operators to clean an area in the machine. How many machines do you currently have that an operator forgot to clean it out and then buckled up some way covers or guards??

|

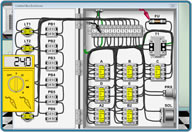

Electrical considerations

|

What type of terminal strip are they going to use? I recommend cage clamp. Why? They apply constant pressure at all times. If there is any vibration, screw terminals have a tendency to loosen up causing premature failure. Most machine tool manufacturers use them now (most of the high quality ones). If you saved one service call because of a loose wire, It paid for itself.

|

Robotic automation

|

Questions to make sure are answered? What type of fixture is recommended? Is it designed for robot load? What kind of chips will be produced? And are they easy to remove with coolant or air blow? Are the clamps single acting or double acting? Double is preferred to prove it is actually unclamped. Do you want to clamp with M-codes or manual push buttons or both. Are you going to need an auto door or servo door. Do you have Extra M-codes and other signals to tap into. |

|

Find system integrators in your area

Automation.com

|