System Integrators- Finding a reputable integrator or automation company

Finding reputable system integrators, Who should you ask?

Probably the best source you will find is to ask your machine tool builders or dealers. Some builders do all of their automation themselves and some use external sources. When they use these external sources, the builders reputation is also on the line, so you can bet their recommendations will be pretty good. Preferably, ask the machine tool builder of the particular machine. Their recommendation will often have more support for getting information and interfacing if it is needed.

-

Tooling salesmen are often great sources for information. They often times use to work for a builder or dealer and are currently visiting many companies and seen many integrations packages.

-

Another good source are salesmen for indexers or rotary tables. The companies that sell them often can't install them. Find out who they use.

What questions should you ask of your system integrator?

Do they do any work for big well known companies? Harley, Ford, GM, Chrysler etc. To become a preferred vendor is often difficult and their requirements are high.

-

Do they do service and repair on machine tools? This is important because they will understand the machine tool logic and know more efficient and easier ways to do things. Plus, if they make a mistake they are able to repair the machine themselves. They will also be able to operate and program the machine to test its functions without the help of your employees. Understanding machine tool logic is both critical for safety considerations and keeping an accidental crash from happening. They did not understand that the machine could do something in a certain situation.

-

Ask for photos of previous work they have done or ask to see to the work of a customer personally.

How systems integrators often cut corners?

-

Avoid providing documentation- Sequence of operations, parts lists, troubleshooting documentation, and prints done in autocad. I can't tell you how many integrators I have seen chicken scratch something on paper and call this a documentation.

-

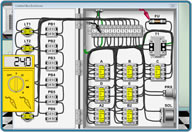

No wire labels are put on.

-

Wires strung across the cabinet, not in wire ways

Should system integrators use the existing machine PLC Ladder or use an external PLC to tie it all together?

I often get the question, "Well, why don't you just rewrite the ladder logic in the machine PLC"? There are a couple of reasons. One reason is if the machine tool builder updates the ladder, this will overwrite any changes that were made for any automation performed. That is the main reason why I would prefer to use an external PLC. Some Builders specifically build a section in their ladder to add custom ladder logic. They also have internal logic bits built into the main ladder to use in the custom ladder, which avoids the need to change the main ladder. Therefore, ladder updates are possible without overwriting automation logic. One thing nice about using their ladder is that every signal is accessible.

If an external PLC is used, most signals to be used for automation are available. These signals can be attained by tapping into wires throughout the machine. The only other thing thing you will need from the builder is external M-codes, which are not always available or written in the ladder logic.

One way is not necessarily better than the other.

Final note: Often a job is never even looked at after it is completed. Look in the electrical cabinet to see if the systems integrator did a good clean job.

|