The process of managing automation Projects from start to finish and dealing with automation contracts can often take alot of time and cost you in the end if things are not handled properly.

The automation supplier will deliver an automation project. But, you must understand what your options are and not assume anything. Always have it in writing. Technical specifications and sequence of operations must be provided to clarify final project expectations. Clarify and delegate each vendors responsibilities. Some of the below items are the most common things in the quoting stages, along with questions and considerations when contracting or doing your automation inhouse.

- Project price

- Recommend types of parts

- Payment terms

- Delivery date

- Clarify responsibilities of all parties involved

- Technical descriptions of the working system and sign off

- Production rate expected

- Capability of hold tolerances

- Possible safety considerations for the system

- Criteria for acceptance of the system at the supplier.

- Criteria for acceptance of the system at your plant

- Scheduling progress meetings and milestone dates

- Procedure for handling changes after the order

- Warranty and Service policies

- Documentation and manuals at completion

- Training expected for operators and maintenance

Stages of automation assembly and project workflow

- Process planning

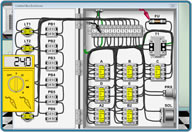

- Design and review electrical, mechanical, and fluid power systems

- Order parts

- Make Sub-assemblies

- Assemble and install at the company

- Program PLC ladder

- Startup

- Debug system

- Review automation, operation and requirements

- Runoff at supplier

- Runoff at the company

- Training

- Complete documentation

Project Documentation provided

Many times this costs extra, so be sure to clarify in the quoting stages and have in writing.

- Sequence of operations

- Electrical diagram

- Mechanical drawings

- Part lists

- PLC ladder program

- Troubleshooting Info.

- PDF versions of all documentation

- Safety warnings