| x |

|

Machine Tool Help.com LLC.

Unbiased machine tool help |

|

||

|

HMI examples |

|

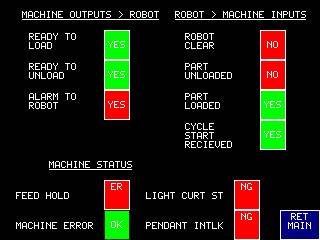

HMI screen examples with Allen Bradley Panel builder

What is an HMI and what does HMI stand for?HMI stands for Human machine interface. HMI's are used as an operator control panel instead of using an excessive amount of hardware and also provides almost unlimited control and status of a fully automated machine cell. Benefits of an HMI system

Below is several screen shots of various HMI status screens that are extremely helpful to have included on all your CNC automation projects screens for CNC interfaces and other machinery and equipment. |

|||||

|

More HMI example programs comming soon

|

GENERAL DISCLAIMER: HELP US IMPROVE THIS WEBSITE..!! Suggestions or comments? Share with everyone? Please Email Me: Thank you for all your contributions and support. |

|

home | purchasing | options & automation | program & applications | installation | Preventative maintenance | troubleshoot | repair | learning | forums | information | links | software & computers | about Machinetoolhelp.com all rights Reserved copyright © 2003-2007 |